Structural Component Advantages:

1. The skirted belt feeder is equipped with a permanent magnet roller and a frequency converter, ensuring metered feeding, effectively removing metal from the raw material, and protecting the mill.

2. The air-locking feeder eliminates air leakage and ensures stable air pressure

3. The main unit utilizes a gear drive and an internal oil pump, eliminating the need for separate oiling or lubrication stations. A cooler also facilitates installation, commissioning, and maintenance.

The inlet volute observation door features a double-layer structure, with the inner door panel and the entire air duct on a single curved surface, effectively eliminating resistance and reducing system energy consumption.

4. The curved air duct effectively reduces wind resistance and air volume loss, minimizing material blockage.

5. The curved scraper allows the entire surface of the grinding roller to grind the material. The combined scraper head is made of wear-resistant carbide, requiring only the head to be replaced when worn, saving spare parts costs.

The new cage-type powder classifier offers higher screening efficiency, and the pulse dust collector collects excess air and dust, preventing powder spillage, ensuring a clean and environmentally friendly environment.

All Our Mill Components

| Manual Rod Valve |  |

Intelligent Grinding Machine |  |

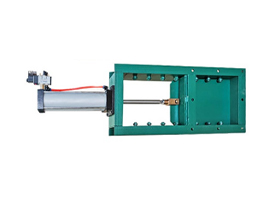

Pneumatic Gate Valve |  |

| Belt Conveyor |  |

Air Classifier |  |

Plate Chain Bucket Elevator |  |

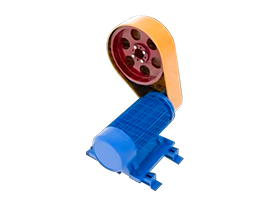

| Gear Reducer |  |

Double Cyclone Separator |  |

Silo Top Dust Collector |  |

| Permanent Magnetic Drum Separator |  |

Baghouse Dust Collector |  |

Level Switch |  |

| Ventilation Fan |  |

Heavy Hammer Valve |  |

Pneumatic Three-Way Valve |  |

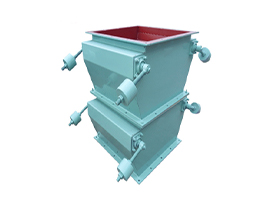

| Lock Hopper Feeder |  |

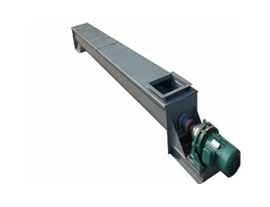

Screw Conveyor |  |

Silo Bottom Bulk Discharger |  |

| Pipeline System |  |

Control System |  |

Large/Small Gear |  |

| Main Grinding Machine |  |

Electric Motor |  |

Jaw Crusher |  |

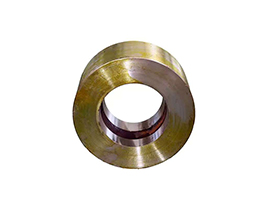

| Grinding Roller |  |

Grinding Ring |  |

Components Specification

| Component | Material | Remark | Yield strength/MPa | Tensile strength/MPa | Elongation | Brinell hardness/HB |

| Large gear | ZG35SiMn | / | / | / | / | / |

| Heat treatment and tempering HB240-280 ultrasonic testing to ensure no internal defects (medium strength, high toughness) | ||||||

| Small gear | 40Cr | / | / | / | / | / |

| Forging heat treatment and tempering + surface quenching HRC40-45 has internal toughness and external hardness, durable and wear-resistant. Ultrasonic flaw detection ensures no internal defects (high toughness and high wear resistance) | ||||||

| Shovel | Medium chromium alloy is made of high wear-resistant alloy steel through vacuum melting and directional solidification technology, with excellent impact resistance and abrasive wear resistance, and a service life of more than 3000 hours. | / | ≥785 | / | / | / |

| Blade disc + blade holder + grinding roller hanger | / | / | / | / | / | / |

| Transmission shaft | 35CrMo forgingAfter quenching and tempering heat treatment, it has high comprehensive mechanical properties (high strength, high toughness) | / | ≥500 | / | / | / |

| Spindle + Grinding roller shaft | 35CrMo forgingAfter quenching and tempering treatment and ultrasonic testing, it is guaranteed to be free of internal defects (high strength, high toughness) | / | ≥835 | / | / | / |

| Grinding Roller + Grinding ring | Mn13Cr2Manganese 13 chromium 2: Excellent wear resistance: The synergistic effect of manganese content and chromium can increase the surface hardness from the initial HB210 to more than HB550 when subjected to high stress impact. After a special heat treatment process, it ensures wear resistance and prevents brittle fracture. The wear life is several times longer than that of ordinary steel, which greatly reduces maintenance costs and downtime. | / | ≥390 | / | / | 213 |

| Snail | NM400 | Model 175 thickness 20CM | ≥1000 | / | / | 360-440 |

| Main fan impeller | NM400Wear-resistant 400: It has high wear resistance, and its wear resistance is 3-5 times that of ordinary steel plates. It also has good impact resistance and can be cut, bent, welded and other processed. It can be connected to other structures by welding, plug welding, bolt connection and other methods. | Thickness 8CM | ||||

| Cage rotor | 16Mn Resistant to high-speed airflow dust erosion and wear, ensuring long-term stability of classification accuracy | Usually refers to Q355 | ≥345 | 470-630 | ≥21% Thickness ≤50MM | 160-220 |

| Powder separator housing | Q235 | / | ≥235 | 375-500 | ≥26% Thickness ≤16MM | 120-180 |

| Cylinder | Q235 | Model 175 thickness 14CM | ||||

| Cyclone | Q235 | Model 175 thickness 6CM 8CM | ||||

| Air lock equipment | Q235 | Model 175 thickness 3 | ||||

| Pipeline | Q235(The abrasiveness is extremely strong, and key parts can be lined with wear-resistant ceramic sheets or wear-resistant steel plates to comprehensively improve the service life of the equipment) | Model 175 thickness 8CM (powder separator pipe) others 3CM |

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى