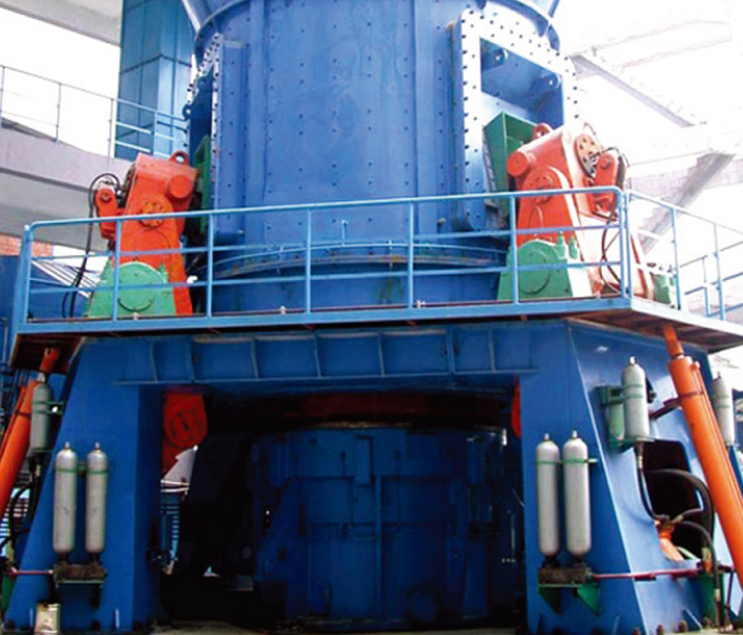

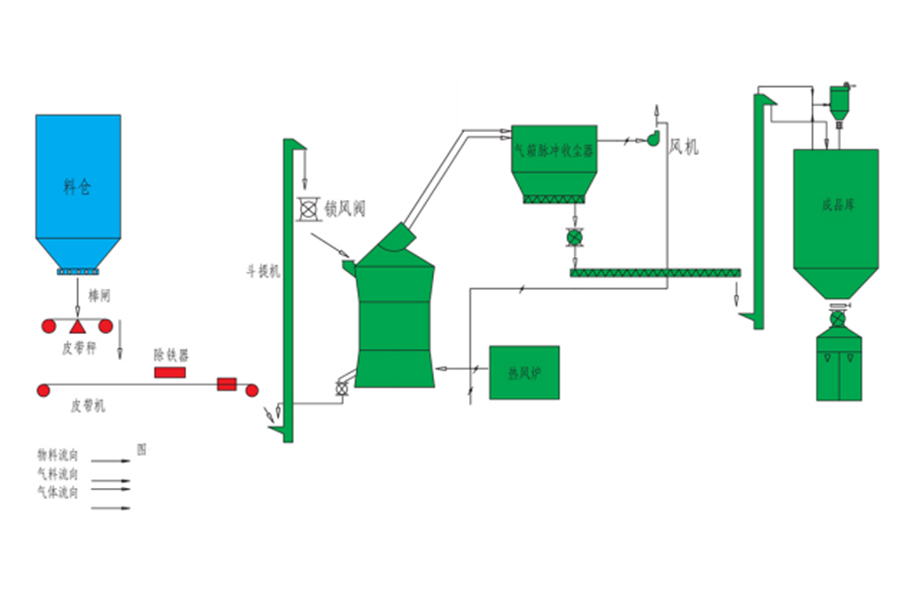

LYH1008 series vertical mill is a new type of equipment designed to absorb foreign technology. It grinds the material (0-15MM) on the rotating grinding disc by rolling the grinding roller with pressure to achieve the corresponding fineness of 325-2000 mesh. The main technology is reflected in the full contact between the grinding roller, grinding disc, and the material and the classification accuracy of the classification system. It is suitable for grinding ultra-fine powder materials in metallurgy, electric power, chemical industry, and refractory materials, especially non-metallic minerals.

The vertical grinding mill integrates the functions of grinding, powder selection, and drying. Compared with other grinding equipment such as ball mill and Raymond mill, it has the advantages of low energy consumption, high grinding efficiency, low wear, strong drying capacity, easy adjustment of product fineness, uniform particle size, easy control of chemical composition, low noise, less dust, simple operation, convenient replacement of wearing parts, simple system process flow, small footprint, and good comprehensive economic benefits. Therefore, the vertical mill is increasingly valued and widely used by the powder processing industry.

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى