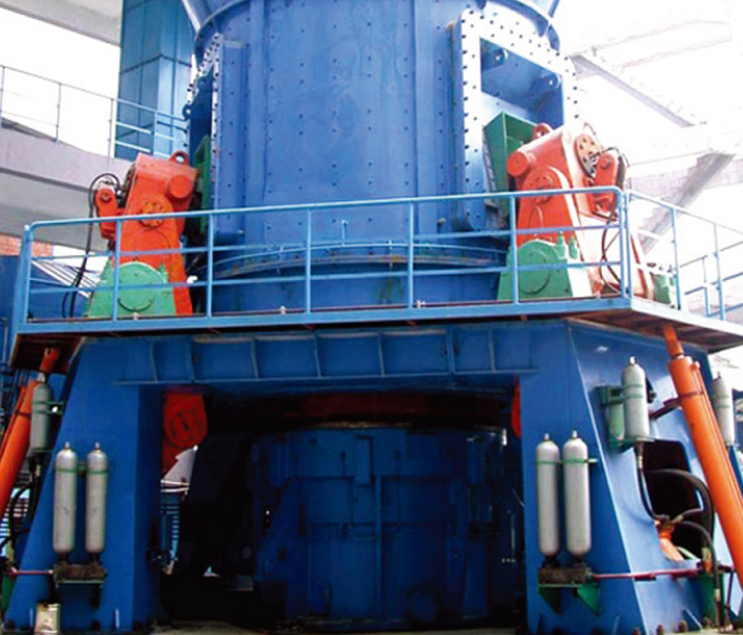

In today’s competitive manufacturing landscape, every business is looking for ways to optimize costs without compromising quality. One of the most effective solutions lies in the use of vertical grinding mills, which offer significant reductions in operating expenses compared to traditional grinding equipment like ball mills or Raymond mills. By lowering power consumption, improving efficiency, and extending the lifespan of key components, vertical grinding mills can have a direct, positive impact on a company’s profitability.

When you choose a vertical grinding mill, you are opting for a system that operates with considerably lower power requirements. Compared to the energy-hungry ball mills, these mills consume up to 40-50% less energy, which translates into long-term savings. The efficiency of a vertical grinding mill comes from its unique design, which allows it to grind materials at a higher rate, utilizing less power. This reduction in energy usage not only saves on operational costs but also contributes to a more sustainable manufacturing process.

Another significant benefit of vertical grinding mills is the reduction in maintenance and replacement costs. These mills are designed with advanced materials for the roller sleeves and linings, which means they experience less wear and tear over time. This high durability reduces the frequency and cost of maintenance, ensuring your equipment remains operational for a longer period without the need for costly replacements. Manufacturers can also benefit from a decrease in metal contamination in the products due to this extended durability, making vertical mills an excellent choice for industries that prioritize product purity.

What’s more, vertical grinding mills come equipped with a range of features that help minimize the overall cost of operation. For example, many models offer external circulation systems that further reduce power consumption and improve product precision. These systems efficiently recycle and reintroduce materials into the grinding process, which enhances energy efficiency while ensuring that the final product meets stringent quality standards.

Space efficiency is another key factor that contributes to the cost-effectiveness of vertical grinding mills. These mills are compact by design, saving valuable floor space compared to traditional grinding systems. This reduction in floor space can lower construction costs by up to 70%, making it an ideal solution for manufacturers looking to maximize their production capabilities without expanding their facility. The integration of crushing, drying, grinding, and transportation into one system streamlines the production process and reduces the need for additional equipment, further enhancing cost savings.

The simplicity of operation in vertical grinding mills also translates into cost savings. With automatic control devices and remote monitoring capabilities, operators can easily manage the mill from a distance, reducing the need for a large on-site workforce. The intuitive controls and reliable performance mean that fewer adjustments are needed, reducing the risk of costly errors or downtime. Moreover, the systems are designed to minimize vibration and noise, which can contribute to a smoother, more efficient operation and a safer working environment.

In terms of product quality, vertical grinding mills also stand out. The material stays in the mill for a shorter period, which makes it easier to monitor and control factors like particle size and chemical composition. With a high-precision classifier included, the mill can produce products with extremely fine particle sizes, ranging from 325 mesh to 2000 mesh. This consistency in product quality ensures that manufacturers can meet the demanding standards of their industries, whether they’re producing fine powders or other precision materials.

Investing in a vertical grinding mill is an investment in the future of your business. By reducing power consumption, minimizing wear and tear, optimizing space, and improving operational efficiency, this technology provides businesses with a competitive edge. Not only does it drive down operational costs, but it also increases the overall productivity and profitability of your manufacturing processes. For companies seeking sustainable, cost-effective solutions without sacrificing performance, vertical grinding mills are the clear choice.

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى