In the competitive landscape of industrial powder processing, energy efficiency is no longer just a performance metric—it's a decisive factor in operational profitability and environmental compliance. The Vertical Grinding Mill , particularly advanced models like the LYH1008 series, plays a central role in achieving this balance by integrating innovative design features that significantly reduce power consumption while maintaining high throughput. Understanding how these systems optimize energy use not only helps operators make informed decisions but also positions manufacturers who offer such equipment as forward-thinking leaders in sustainable production.

One of the most impactful strategies employed in modern vertical grinding mills is thermal integration, where waste heat from other processes or ambient air is utilized to dry raw materials inside the mill. This reduces the need for additional heating elements and lowers overall energy input. In the LYH1008 model, an optimized airflow path ensures even heat distribution, allowing moisture-laden feedstock to be dried efficiently without compromising grinding performance—a key advantage over traditional ball mills that often require separate drying units.

Motor and drive technologies have also evolved to enhance the energy efficiency of vertical grinding mill operations. High-efficiency motors with variable frequency drives (VFDs) allow for precise control over rotational speed and torque, adapting to fluctuating load conditions in real time. This dynamic adjustment prevents unnecessary energy spikes and extends motor life. Additionally, regenerative braking systems—where applicable—can recover some kinetic energy during shutdowns or speed reductions, further improving the system’s overall energy profile.

Airflow optimization within the mill chamber contributes significantly to energy savings. By minimizing pressure losses through streamlined ducting and improved classifier designs, the vertical grinding mill can maintain high internal circulation rates with reduced fan power. The LYH1008 integrates aerodynamic enhancements that lower resistance and ensure smooth material transport, reducing the burden on auxiliary systems and contributing to a more energy-conscious operation.

Intelligent control systems are another cornerstone of energy-efficient vertical grinding mill setups. These systems monitor variables such as feed rate, pressure, temperature, and particle size in real time, adjusting parameters automatically to maintain optimal performance. In the LYH1008, this level of automation allows for consistent output quality while avoiding over-grinding or underutilization—both of which lead to wasted energy. For customers, this means lower operational costs and greater predictability in production cycles.

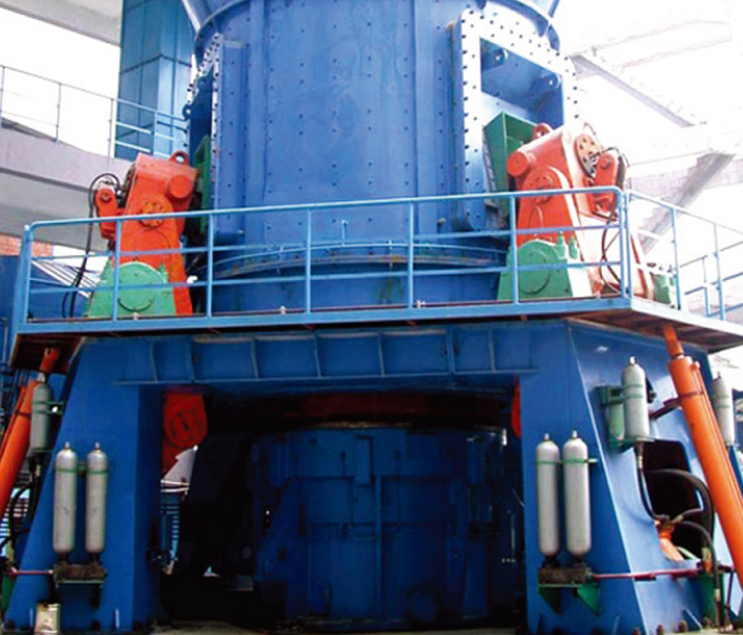

Beyond direct energy-saving mechanisms, the overall mechanical efficiency of the vertical grinding mill should not be overlooked. With fewer moving parts and a compact structure, vertical mills inherently consume less energy than their horizontal counterparts. The LYH1008 further enhances this advantage with wear-resistant components and low-friction bearings that minimize mechanical losses. When combined, these features translate into measurable cost reductions across the lifecycle of the equipment.

For powder processing businesses aiming to stay ahead in both economic and environmental terms, choosing an energy-efficient vertical grinding mill like the LYH1008 is a strategic move. It reflects a commitment to innovation, sustainability, and long-term value—qualities that discerning buyers look for when investing in industrial equipment. As global demand for fine powders continues to rise, so does the importance of intelligent, energy-conscious manufacturing solutions.

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى