When evaluating grinding equipment for industrial-scale applications, the upfront investment often overshadows what truly matters over time: lifecycle cost. While ball mills and Raymond mills have been the traditional workhorses in grinding operations, the Vertical Grinding Mill has rapidly gained preference in modern plants for its substantial advantages across multiple cost dimensions. It's not just about saving energy—it’s about maximizing efficiency, reliability, and long-term returns.

In terms of power consumption, vertical mills outperform conventional systems by a significant margin. Ball mills are known for their high energy use, particularly when fine grinding is required. In contrast, the Vertical Grinding Mill delivers superior grinding efficiency with 40–50% lower power consumption. This isn’t just an energy-saving statistic—it translates into lower utility bills, reduced load on plant infrastructure, and measurable savings that accumulate month by month. For facilities operating under tight margins or striving for energy optimization, this difference is not minor—it’s transformative.

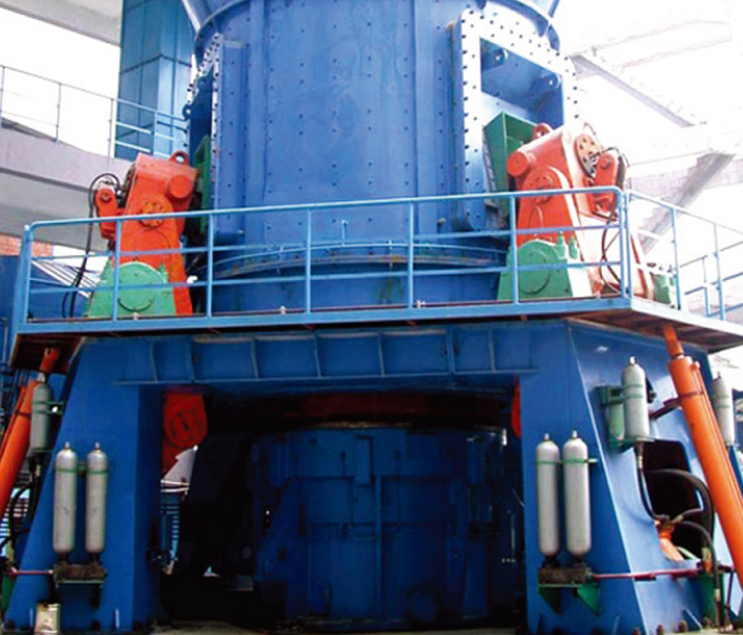

Capital costs also tell a compelling story. The integrated design of a vertical mill—combining grinding, drying, and classification in a single compact unit—requires less floor space, fewer auxiliary systems, and simpler foundations. Compared to a ball mill setup, a Vertical Grinding Mill installation can reduce construction costs by up to 70%. This means not only quicker installation but also lower engineering complexity and easier plant layout integration. Especially for greenfield projects or plant upgrades, this cost efficiency can be the key to staying competitive in today’s markets.

From an operational perspective, vertical mills offer a level of automation and stability that traditional mills struggle to match. Equipped with modern control systems and intelligent feedback loops, a vertical grinder allows real-time adjustments to optimize product quality and throughput. Unlike the Raymond mill, which often requires manual tuning and suffers from fluctuation in output size, a Vertical Grinding Mill ensures consistently fine and precise results—critical when producing materials like calcium carbonate or fly ash that demand tight particle size distribution.

Maintenance, often overlooked in cost calculations, can make or break long-term equipment performance. The design of vertical mills emphasizes accessibility: roller sleeves and liners can be changed quickly with minimal manpower and downtime, thanks to smart hydraulic systems. In contrast, ball mills typically require more labor-intensive and time-consuming maintenance procedures. Reduced wear and optimized material contact in vertical mills also mean fewer part replacements and less disruption, ensuring your production lines keep moving with fewer surprises.

When considering environmental and regulatory implications, vertical mills offer another layer of advantage. The enclosed, negative pressure operation dramatically reduces dust emissions and noise pollution, improving workplace safety and supporting compliance with environmental standards. With increasing attention to ESG goals and regulatory scrutiny, these built-in design benefits of the Vertical Grinding Mill offer more than just operational comfort—they’re part of a forward-looking strategy for responsible production.

In the end, selecting a Vertical Grinding Mill is not just a technical upgrade; it’s a strategic decision. For businesses looking to modernize their grinding operations, minimize operating risk, and ensure scalability for future needs, vertical mills present a powerful case. As a manufacturer deeply experienced in grinding technology and equipment engineering, we believe this shift isn't a trend—it's the new benchmark. If you're considering a long-term investment in efficient, low-maintenance, high-performance grinding, it’s time to look beyond legacy systems.

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى